-

Vectric Software for the Absolute Beginner – Part 42

-

Vectric Software for the Absolute Beginner – Part 41

-

Vectric Software for the Absolute Beginner – Part 40

-

Vectric Software for the Absolute Beginner – Part 39

-

Vectric Software for the Absolute Beginner – Part 38

-

Vectric Software for the Absolute Beginner – Part 37

-

X and Y Axis Identification and Rotation

-

Vectric Software for the Absolute Beginner – Part 36

-

Vectric Software for the Absolute Beginner – Part 26

-

Vectric Software for the Absolute Beginner – Part 25

-

Vectric Software for the Absolute Beginner – Part 24

-

Vectric Software for the Absolute Beginner – Part 23

-

Painting and Finishing a V-Carved Project

-

Vectric Software for the Absolute Beginner – Part 22

-

Vectric Software For the Absolute Beginner – Part 21

-

Vectric Software for the Absolute Beginner – Part 20

-

Vectric for the Absolute Beginner – Part 19

-

Vectric Software for the Absolute Beginner – Part 18

-

Vectric Software for the Absolute Beginner – Part 17

-

Vectric Software for the Absolute Beginner – Part 16

-

Vectric Software for the Absolute Beginner – Part 15

-

Vectric Software for the Absolute Beginner – Part 14

-

Vectric Software for the Absolute Beginner – Part 13

-

Vectric Software for the Absolute Beginner – Part 12

-

Vectric Software for the Absolute Beginner – Part 11

-

Vectric Software for the Absolute Beginner – Part 10

-

Vectric Software for the Absolute Beginner – Part 9

-

Vectric Software for the Absolute Beginner – Part 8

-

Vectric Software for the Absolute Beginner Part – 7

-

Vectric Software for the Absolute Beginner – Part 6

-

Vectric Software for the Absolute Beginner – Part 5

-

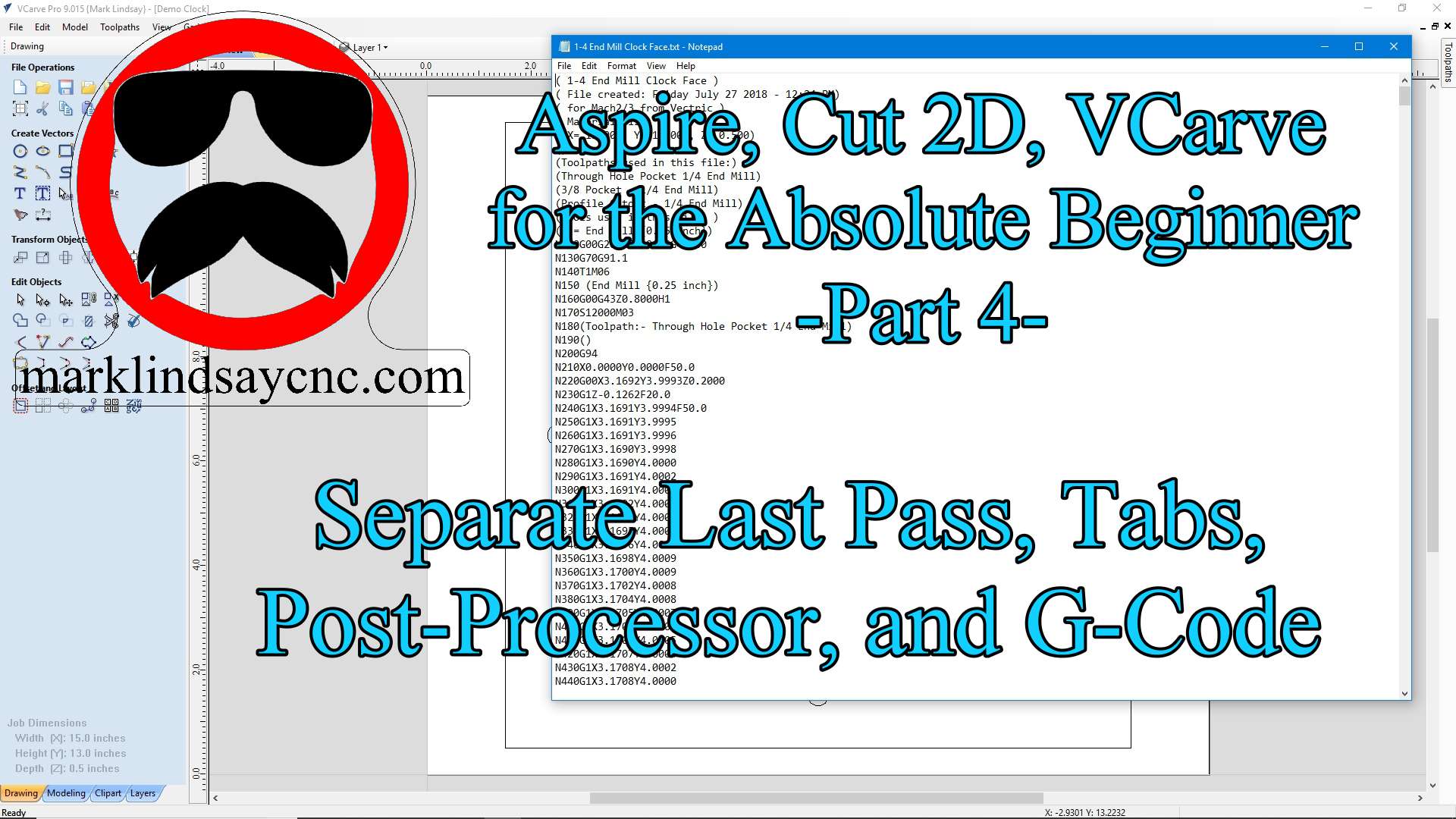

Vectric Software for the Absolute Beginner – Part 4

-

Vectric Software for the Absolute Beginner – Part 3

-

Vectric Software for the Absolute Beginner – Part 2

-

Vectric Software for the Absolute Beginner – Part 1

-

Creating a Spoilboard Surfacing Toolpath in VCarve

Surfacing a spoilboard is the final necessary step, after laying one down on the CNC table. Creating the surfacing toolpath sounds intimidating, but it’s actually pretty simple. You just have to remember a couple of things. [expand title=”Read More”] Why Surface a Spoilboard? The simple answer is that we surface the spoilboard to make sure that it’s flat and smooth. Material to be cut on the CNC is mounted to the spoilboard. We want that material to be as flat as possible to ensure smooth cuts of equal depth along every part of its surface. This is especially important when it comes to v-carving or engraving. If the work piece…