Vectric Software for the Absolute Beginner – Part 37

Part 37 – Adding a Form Tool to the Tool Database Using a Vector This article accompanies the thirty-seventh video

A hobby CNC enthusiast's blog

I’ve wanted to add a rotary axis to my CNC since I built my first Shoestring Budget CNC back in

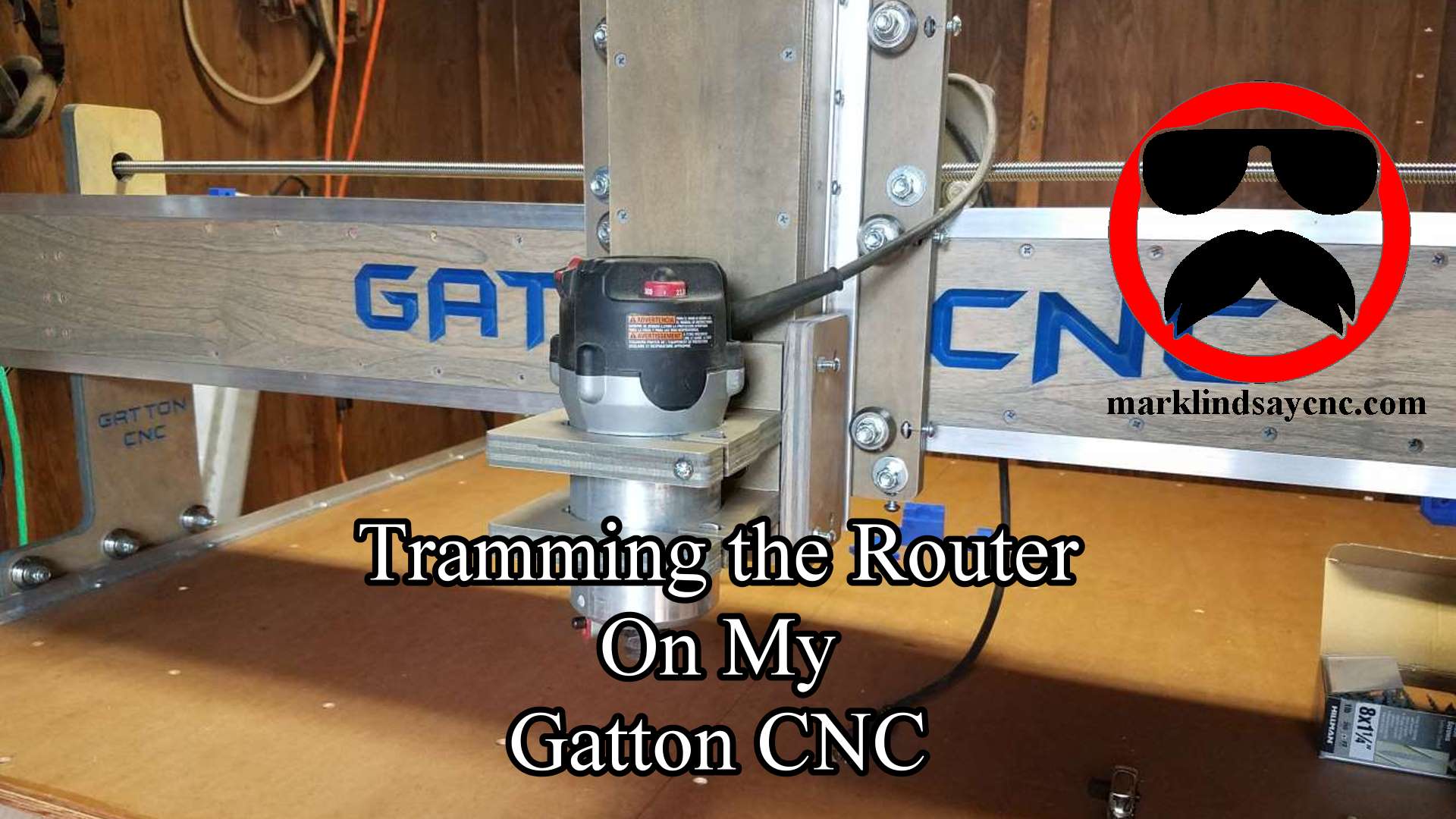

What Is Tramming and Why Would You Do It? Tramming the router means adjusting the router mount to get