-

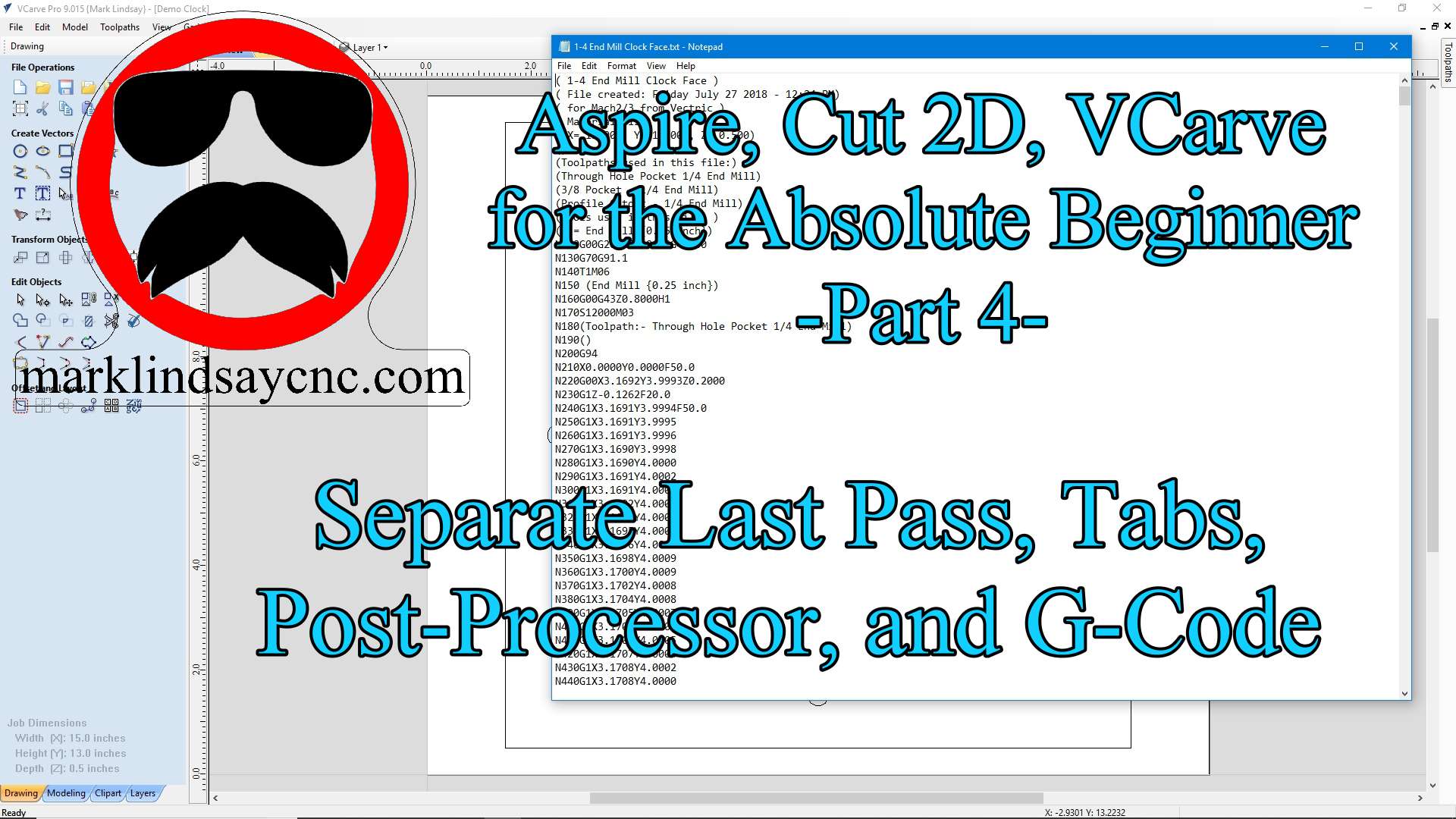

Vectric Software for the Absolute Beginner – Part 24

-

Vectric Software for the Absolute Beginner – Part 23

-

Painting and Finishing a V-Carved Project

-

Vectric Software for the Absolute Beginner – Part 22

-

Making My CNC Table Alignment Jig

-

Vectric Software For the Absolute Beginner – Part 21

-

Vectric Software for the Absolute Beginner – Part 20

-

Vectric for the Absolute Beginner – Part 19

-

Vectric Software for the Absolute Beginner – Part 18

-

K40 Laser Unboxing